2D Codes

Increasing Usage

There’s a global movement to increase adoption of 2D codes across many sectors, including construction and manufacturing, but it’s retail that’s leading the charge. Alongside regulatory changes, GS1 (the global standards organisation for barcodes) has announced the official sunrise period for 2D codes will start in 2027. As a key member of the GS1 2D Solutions Group, we advise businesses on moving from concept to production in all packaging requirements around 2D codes.

Variable Data – Maximising the Use of 2D Codes

When making the transition from linear 1D barcodes to 2D codes, there’s a whole range of benefits beyond simply embedding a URL. The real power of 2D codes in smart and intelligent packaging is unlocked when combined with variable data, particularly for supply chain efficiency.

Maximise the Benefits of 2D Codes by Improving the Data Application

Supply chain

2D codes can be printed on individual products, packaging, or labels to provide a unique identifier for each item. This enables accurate tracking and tracing throughout the supply chain, from manufacture and distribution through to retail. Scanning the code provides quick access to information about a product's origin, batch number, expiry date, and other relevant details.

DDRS and the circular economy

Digital Deposit Return Schemes are now being trialled and will improve levels of recycling by rewarding consumers for returning their recyclable packaging. Each one can be identified by a unique QR code.

Waste reduction

Real-time visibility helps prevent stockouts, minimise overstocking, and improve overall inventory accuracy. 2D codes can be placed on products that need to be cleared from inventory, with dynamic pricing (decreasing as a product approaches expiry) incentivising customers to purchase quickly and thereby minimising waste.

Authentication & anti-counterfeit

We work with key solution providers who generate 2D codes incorporating security features to deter counterfeiting and unauthorised replication. By scanning the codes, customers, retailers, and inspectors can verify the authenticity of a product.

Traceability

In the event of quality issues or product recalls, 2D codes facilitate swift identification and isolation of affected items. Supply chain personnel can quickly retrieve relevant information, such as the batch, manufacturing date, and other critical details, enabling efficient containment and resolution.

Consumer promotion

Brands can leverage unique 2D codes to engage with consumers and create individual messages and promotions. This allows for more effective targeting, with each code leading to a customised landing page, offering a tailored consumer experience. Al can be harnessed to track, segment, and analyse consumer engagement, enabling a truly data-driven marketing approach.

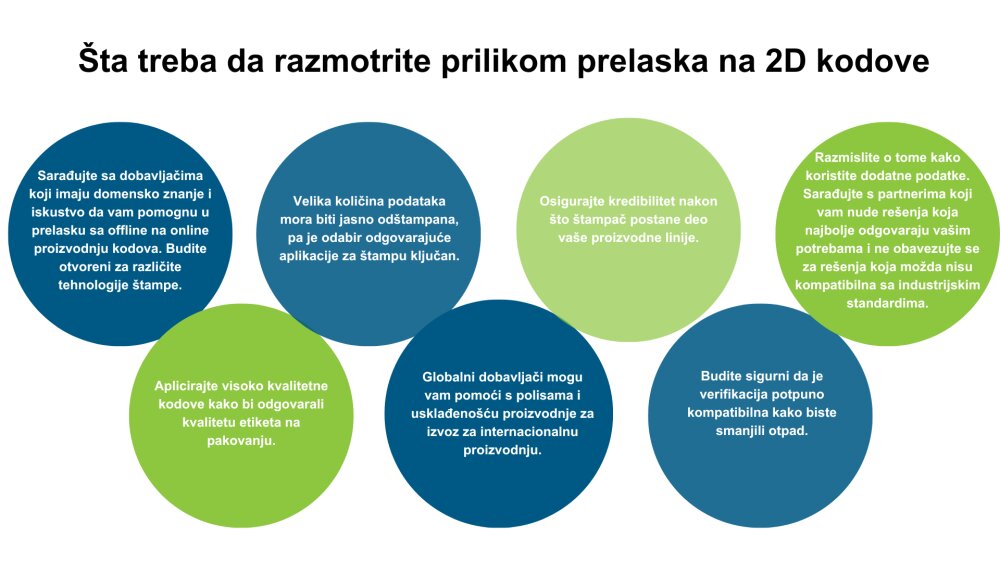

Understanding Your Requirements

When transitioning from linear barcodes to 2D codes, it’s essential to choose a partner with broad experience – not just a hardware supplier - and specialist knowledge to maximise the benefits and minimise disruption. The change will often involve moving from offline to inline printing, to allow variable data such as batch number and serialisation to be included in the code.

We have vast experience printing 2D codes across diverse industries, with a comprehensive product range that ensures high-quality print on a wide variety of materials. Our portfolio spans the full spectrum of coding and marking capabilities, from thermal inkjet and laser through to an excellent range of digital printers, allowing for late-stage customisation of variable data, printing unique codes for short run and high-volume requirements.

The Advantages of Digital Printing

Digital printing for packaging brings a host of advantages, particularly in terms of productivity, short runs, application of variable data, and waste reduction.

Traditional printing methods often require costly setup processes, such as plate making, which can be inefficient and expensive for small volumes. Digital printing eliminates these setup costs, offering significant cost savings for short print runs.

Digital presses also use much less material for changeovers, resulting in substantial savings – this is not only important when media is scarce, it also saves costs and reduces paper and ink waste.

Another key area for digital printing is the application of variable data. Digitally printing labels and packaging allows more granular product data, including barcodes, serial numbers, and unique 2D codes for product tracking and inventory management.

Contact us regarding our innovative solutions for product printing and labeling.