Elmed's Innovation Center: Systems tailored to your needs

Have you ever wondered what is the right recipe for a successful company? The answer is very simple, there is no recipe.

You need to be interested in what you do, listen the needs of the market and be proactive in following innovations in your field.

It's that simple.

At Elmed we try to expand our field of activity, by listening to client requests, introducing new technologies into the process and professional training for our employees, in order to offer the market as wide a range of specific solutions as possible.

Annually, we manage to complete about 6-7 large projects, on which over 30 colleagues of various profiles work, such as mechanical and electrical engineers, automatists, roboticists, specialized masters for working on machines for the production of individual parts, masters for assembling and testing machines, software developers and other. All of them together form a real team for the construction of a custom-made system according to your measurements.

Development directions:

The development process has been influenced by various factors such as market trends, client requests, economic currents, and strivation of improvements in internal production processes, so our development went in several directions.

1. Client request

It happened that a client contacted us with a specific request because no one had solved their specific problems with production lines.

We always looked forward to new challenges, and it was even better if we could successfully overcome those challenges. At the end of the day, we would be satisfied with the new experience, as well as our client, because thanks to us, he would be able to overcome the obstacles in his work.

2. Investigation from the field

Our sales representative comes with a new idea from the field. In that case, he would analyze the client's production environment more deeply and see what type of system could help him achieve even better results. He would present the proposal, and if the client accepted it, we would come up with a solution together.

3. Market analysis

Following world trends, we would often be able to see a new market demand for specific systems that do not exist as such here. Then, we would work on developing it on our own initiative. We are not afraid to break the ice.

4. Internal development

Our development did not always go in an external direction, we were also working on internal projects as well, such as Loupe Machining software, which facilitates the organization of work in production, and TMS software, the application that helps us to better organize the delivery of our goods.

Project life cycle:

1. Technical negotiations

The whole process starts when the sales representative contacts the client for the first time. Then he fills out questionnaires to better understand his requirements internally. After that, the Project Manager and technical persons of the appropriate profession are involved in order to start technical negotiations with the client.

2. Specification of client requirements

A document is created by our team with all clearly defined user requirements, timelines and details related to quality and finances.

3. Design Creation

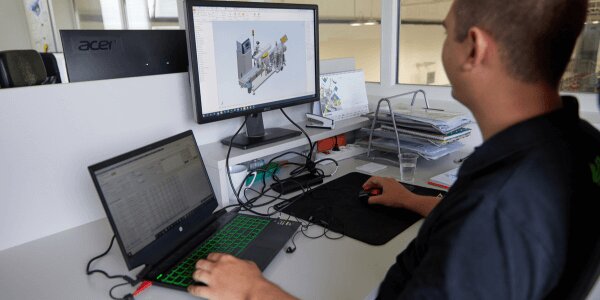

During this phase, the development team starts designing the mechanical or automation part of the project, with constant collaboration with the client and making revisions until the final design is confirmed by both sides.

4. Production of equipment/systems

First, we start with the production of individual parts and we monitor everything with the help of our Loupe Machining software, which enables us to monitor the total production more easily and calculate the required time better until we finalize and assemble the entire system intended for delivery to the customer. Quality control and functional tests are then carried out to make sure that the system meets the strict quality criteria.

5. Installation

Our engineers, technicians and repairmen install the manufactured equipment in the client's facilities and try to disrupt or interrupt the existing production process as little as possible. Very quickly, ELMED's latest manufactured system is integrated into the client's production cycle, and together we have the opportunity to enjoy a successfully executed project. Although this is the step we aimed for throughout the entire project, it is not the last in the life cycle of the equipment delivered to the client, because our cooperation continues through service support, aftersales, as well as any modification or modernization of existing equipment in the future.

Duško Alavanja, Production & Development Department Manager

I am proud of all the people I work with because I know that they give their best every day to make a system according to all requirements. There are challenges, especially when multiple parties are involved, so everything needs to be communicated and rooted out in the right way that there is no confusion. We communicate internally within 3 teams and externally with subcontractors and client teams. It all has to sync perfectly.

I have worked in Elemed for 5 years now, and in all this time, we have never failed to realize a project and all the requirements it brought with it. We have behind us a large number of projects that are all different and proof of our expertise.

Service Support

We stand behind every system we produce, and to prove it, our clients have 24/7 service support as well as aftersales for all the necessary parts and upgrades throughout the life of the system that was built, in order to extend its working life. in a profitable way.

Our service centres are located in different locations in the region so that we can react as quickly and effectively as possible, should a stoppage occur.

They are always available for regular maintenance of our client's machines, but also for unforeseen circumstances. 062 HELP US (062 4357 87)

Individual production:

We have done over 5,000 installations in different production environments so far for different industries such as the food and beverage industry, automotive, banking industry and others. You can check out some of our favourite projects.

- Flora Bečej

- Sistem za apliciranje akciznih markica na farma kutijicama

- Carnex WMS

- Metalac sa robotom

- Formaideale obeležavanje na 15 linija

- RB global konusni proizvodi

- Heineken i Nectar inspekcija limenki

- JUB etiketiranje kanti

- Loupe Machining

Ivan Crnojević, CEO Elmed

We have big plans for the further growth of the Elmed company. In the next few years, we aim to continue introducing innovative solutions and expand our development team in order to contribute to the urbanization of the society in which we live, while constantly advocating for the reduction of environmental pollution and at the same time providing our customers with the latest technologies in the field of industrial marking. We will continue to follow world market trends in the production of self-adhesive labels as well. Whether it is blank, colour or premium labels, and try to keep up with the change of tides.