Industry 4.0

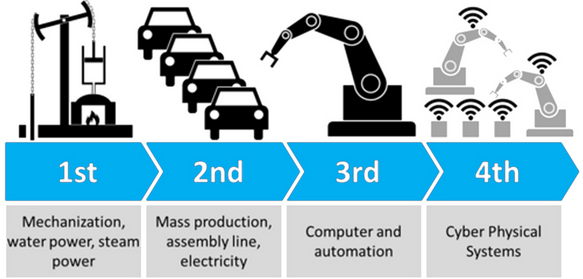

The term Industry 4.0 has been a hot topic of discussion in manufacturing over the last 2-3 years. However, do people really know what it means and more importantly are they implementing its practices? The term Industry 4.0 was coined to represent the 4th industrial revolution and a nod to high tech naming techniques (version name point zero). According to KPMG, Industry 4.0 is a collective term used around the world to describe the convergence of IOT (internet of things) driven technologies, augmented decision making and advanced automation. These next-generation technologies are fundamentally transforming the traditional value chain by opening new revenue streams and driving a step change in business performance.

Suggested 6 key dimensions of Industry 4.0

- Strategy and business model,

- Technologies & systems,

- Goverance & risk management,

- People,

- Operational excellence,

- Customer experience.

A recent survey found a mere 27 % said their company was ‘investing in Industry 4.0’, with a third answering negatively (33 %), and 40 saying they didn’t know. This shows a significant amount of uncertainty manufacturing companies surrounding the term.

Most people see the logic in IOT & using automation to increase productivity on the manufacturing floor but from our experience in coding & marking solutions, our technical team at ELMED still witness large manufacturers wasting time manually typing in codes and selecting messages. These manual practices can be a risky. We have seen product recall after product recall enforced due to wrong dates printed on to product packaging. This can be harmful to a brand’s image and costly to the bottom line not to mention friction with the public and the retailers.

Coding Automation

ELMED have been working tirelessly over the past 2 years putting together a new way of thinking. Our new direction promotes the following tools to help achieve new Industry 4.0 standards: coding & line automation, systems integration, data transfer, bar code reading, print inspection via vision systems, intelligent labelling, remote monitoring of printers and preventative fault information via cloud.

What are the benefits of Coding Automation?

- Seemless message syncronisation between your ERP/MES/Database and Domino printers across production lines,

- Increases production efficiency and reduces the amount of time spent manually inputting messages,

- Reduces coding errors and possible product recalls,

- Ensures accuracy and speeds up label application across primary, secondary and tertiay packaging levels (pack, carton & pallet),

- Allows messages to be sent from a central location and confirmation at floor level before printing,

- Complete traceability when connected to a vision system for Code Check capabilities,

- Remote printer monitoring when using Domino Cloud.