Navigating the Polycrisis: Four Tips for Turning Supply Chain Challenges into Opportunities

Has your business been hit with component shortages, excess shipping fees, production delays, and subsequent loss of business? You are not alone.

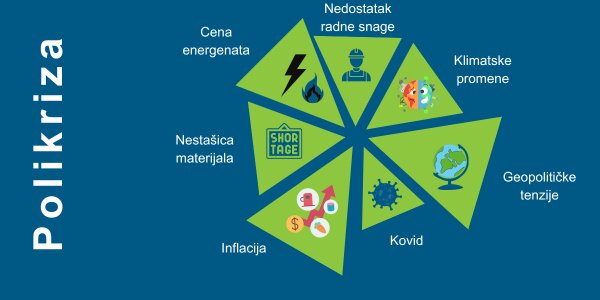

The world is reeling from the ongoing effects of what has recently been dubbed the ‘polycrisis’ – a long line of complex, connected, and cascading crises, including the climate emergency, the COVID-19 pandemic, the conflict in Ukraine, and other geo-political events, which have set supply chains in turmoil and made any attempt at conducting ‘business as usual’ exceptionally challenging.

The polycrisis has emphasised the need for resilience, adaptability, and innovation in manufacturing. In this blog, we will highlight four tips for manufacturers to help navigate current supply chain challenges and discuss what steps to take and what technology to invest in to turn current challenges into opportunities.

The impact of supply chain challenges

- Production and shipping delays: lack of raw materials and components can cause delays in production, shipping, and supply, resulting in missed deadlines and lost revenue.

- Inventory management issues: excess inventory from delayed shipments can tie up capital and warehouse space, while a lack of inventory due to delays in materials supply can lead to lost business opportunities.

- Quality control issues: when faced with shortages, manufacturers may look outside of their typical supply chains to source stock, opening the potential for substandard, faulty, or counterfeit components that can affect the quality of the final product.

- Increased costs: delays in the manufacture and shipping of products can lead to higher costs, overheads from shipping and storage fees, and penalties for late deliveries.

- Penalties: shipping delays and missed orders may result in financial penalties and loss of business.

- Customer dissatisfaction: manufacturers unable to deliver products on time due to stock shortages and supply chain bottlenecks may lose deals with their end customers, leading to loss of revenue, breakdown of relationships, and potential long-term brand damage.

Turning challenges into opportunities

It’s a stressful time for manufacturers – but rather than waiting for supply chain challenges to pass, businesses can take steps to adapt. Those that do may find new opportunities for growth and success.

1. Increase traceability and visibility

Having full, end-to-end traceability of products and supply chains can help brands identify inefficiencies and causes of waste or leakage, and so optimise their operations, improve resilience, and manage risk. During periods of high demand or when faced with stock shortages and delays, this increased visibility can help to accurately forecast lead times, control stock requirements, and manage customer expectations.

Product traceability and supply chain visibility can be facilitated with variable product data embedded within scannable 2D codes added as part of the production process without necessitating changes to product packaging. Introducing scannable 2D codes equipped with batch and product information can allow more data to flow through the supply chain, providing options for brands and supply chain partners to track products upstream and downstream and provide status updates.

Beyond navigating the current supply chain challenges, the addition of 2D codes on product packaging can have huge commercial benefits for brands – in everything from consumer engagement to waste reduction and counterfeit protection.

2. Explore options for late-stage customisation

When raw materials are in short supply, flexibility is vital – late-stage customisation of product packaging can provide the flexibility that companies need to respond to last-minute changes to production runs due to material shortages.

High-resolution, digital printing technologies are now evolving for use within production lines, allowing manufacturers to bring more packaging customisation within the factory walls. In everything from food and beverage to pharmaceutical applications, in-line or near-line printing enable manufacturers to adjust product labels in response to material availability without relying on last-minute shipments from external packaging providers.

Moving forward, brands with the capacity for late-stage customisation of product packaging may find themselves better able to respond to changes in labelling legislation, embrace new markets and language variations, and create promotional packaging for short-run campaigns – without excess wastage or costs from minimum order requirements.

3. Embrace smart technology and automation

Materials shortages can cause significant issues on production lines, necessitating last-minute changes to production runs and requiring lines to work overtime to meet commitments when shipments arrive. Manufacturers also struggling with labour shortages can find themselves hard placed to respond to such challenges and remain productive.

Smart technology and automation can lend a hand – helping manufacturers to flex production capabilities without relying on additional manual labour to meet demand. Manufacturers can utilise Industry 4.0 processes and automate systems to take care of routine tasks and reallocate the human workforce to where it’s needed most to ensure that products continue through production and out of factory doors.

Companies investing in performance-enhancing technology today will find themselves better equipped to handle future challenges – in the long term, automation can reduce running costs, eliminate errors, and improve resiliency and productivity.

The complex nature of the polycrisis makes it unlikely that the challenges causing supply chain issues will be mitigated any time soon. It’s no quick fix, but some businesses with traditional global supply chains are seeing benefits from investment in small-scale, agile production facilities or ‘micro-factories’ in key production areas.

Strategically placed, high-tech production facilities can bring additional benefits well beyond the current crisis by being located closer to the end-users or markets they serve. Benefits include reduced transportation costs and delivery times, as well as options for additional value creation in local markets, helping to differentiate brands from competitors and drive profits.

4. Collaborate for success

You are not alone.

Challenges are easier to tackle if everyone works together. Manufacturers should embrace a culture of open innovation, and collaborate with suppliers, retailers, logistics providers, end customers, and all other supply chain partners to better understand current challenges and develop creative solutions to universal problems.

A closer, more collaborative supply chain can help build trust and provide opportunities for companies to demonstrate their commitment to responsible business practices and showcase their problem-solving abilities.

At Domino, we recognise the value of collaboration in developing new systems and solutions to overcome current manufacturing challenges. We are committed to working with our customers, supply chain partners, and brands from across industries to achieve better outcomes.

Learn more about our approach. Contact us today.