05. Aug 2022.

What is product handling? The foundation of high-quality codes for traceability

Two-dimensional barcodes are becoming a common addition to product packaging – with factors such as globalisation, online trading, and the need for stronger anti-counterfeit methods driving their uptake. In several industries, including European tobacco and pharmaceuticals, 2D codes are now a regulatory requirement.

09. Jun 2022.

Elmed doo won the recognition for special contribution to the development of the economy of the South Bačka District

The Chamber of Commerce and Industry of Serbia - the Regional Chamber of the South Bačka District awarded companies and business leaders who stood out with their work, dedication and results in 2021.

27. May 2022.

06. May 2022.

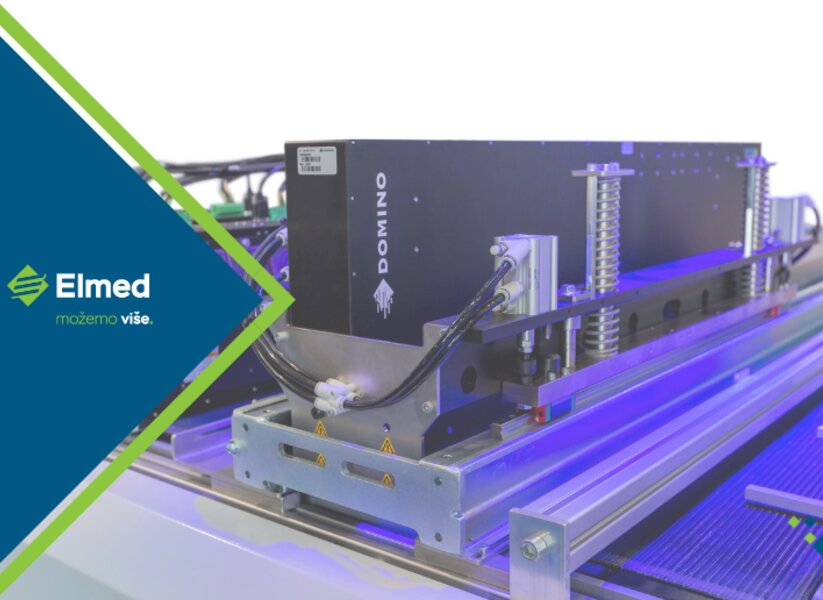

Discover the unique intelligent Technology features within Domino’s K600i digital inkjet printer

The K600i is based on Domino’s proven and reliable Generation 6 inkjet technology, of which there are approaching 1000 global installations.

18. Apr 2022.

Direct part marking with thermal inkjet (TIJ)

The need for marking parts is found across many industries including aerospace, automotive, construction materials, electronic components, and extrusion applications.

Parts are directly marked in the production process for various reasons. To list but a few: differentiating and identifying similar-looking parts, supporting the assembly, indicating a quality check or other process has been successfully passed or enabling to trace the part back to the production line.

Parts are directly marked in the production process for various reasons. To list but a few: differentiating and identifying similar-looking parts, supporting the assembly, indicating a quality check or other process has been successfully passed or enabling to trace the part back to the production line.

08. Apr 2022.

Future on board, maintenance on site

New innovative features for the HERMA 500 label applicator

25. Mar 2022.

What is an industrial Continuous Inkjet (CIJ) printer?

CIJ is short for continuous inkjet. In a CIJ printer, ink is pumped from an ink reservoir and ejected through a nozzle that creates a jet of ink.

28. Jan 2022.

The best technologies for coding onto cartons

The food and pharmaceutical sectors rely heavily on the use of cartons. Your ability to apply clear, durable codes at variable – and often high – speeds is crucial to operational success. So what are the best technologies for coding onto cartons – and how do they tackle the unique coding challenges of the food and pharma sectors?

12. Jan 2022.

Accelerating the digitalisation of supply chains: managing Brand Risk, enhancing the consumer experience, and removing defects

For many years, adding coding and marking technology to your manufacturing line was perceived simply as a compliance obligation. Now, with the advent of more complex requirements for supply chain trackability, coupled with increasing consumer demands for personalisation, provenance checks, and anti-counterfeit protection, that ‘simple’ coding and marking technology can be a big stepping stone towards both a fully-connected supply chain and an enhanced, interactive consumer experience.

30. Dec 2021.

20. Dec 2021.

What’s the difference between a Data Matrix Code and a QR Code?

QR codes and Data Matrix codes are both 2D barcodes or ‘2D codes’ and are both becoming much more commonly used by manufacturers but in very different ways.

From extending product packaging to communicate brand messaging to providing options for internal track and trace and anti-counterfeiting measures, 2D codes can offer a wealth of opportunities for manufacturers in all industries.

But, which 2D code is right for your business?

From extending product packaging to communicate brand messaging to providing options for internal track and trace and anti-counterfeiting measures, 2D codes can offer a wealth of opportunities for manufacturers in all industries.

But, which 2D code is right for your business?

04. Nov 2021.