Recycle Revolution: On Pack Recycling Labels Make Doing the Right Thing Easier Than Ever Before

In October 2018, the Ellen MacArthur Foundation and the UN Environment Programme launched the New Plastics Economy Global Commitment to create a circular economy for plastics. Since this date, more than 500 signatories have signed up, and many large global brands have made promises to drastically increase their use of post-consumer recycled (PCR) plastic while reducing the use of virgin plastic by 2025.

Individual commitments for PCR plastic use range from 20% to 100% – with an aggregate target of 26%. The commitments are laudable, and many brands have taken great strides in the right direction, but a problem remains – there is not enough recycled plastic to meet this demand.

In its 2022 global report, the Ellen MacArthur Foundation announced that signatories had more than doubled their use of PCR since 2018 – from 4.8% to 10% – but remain a way off the 2025 target. Moreover, virgin plastic use is back at 2018 levels after an initial drop.

The question remains, how can we increase the quantity and availability of PCR plastic? In this blog, we will look at what brands can do to make it more likely that their product packaging will be recycled, time and time again.

Creating a circular economy for plastic waste

If you are involved in product packaging design, there are a few key things you can do to help boost the chances of product packaging being recycled, which are covered in our previous blog on sustainable packaging design.

That said, making products recyclable is only part of the solution. Worldwide, we produce large volumes of recyclable waste daily, but this often finds its way into general waste collections. Indeed, a recent report by National Geographic found that 91% of plastic waste is not sent to a recycling facility.

How can we improve the quantity of recycled plastics?

Conversation is rife around how to improve materials recovery. Multiple startups and businesses aim to improve product identification at materials recovery facilities (MRFs), with everything from artificial intelligence and machine vision applications emerging alongside existing near-infrared and air separation technologies to identify waste better and increase recycling rates.

However, Dr Adam Read, Chief Sustainability and External Affairs Officer, SUEZ Recycling and Recovery UK, suggests a more practical solution could be found closer to home.

“Our MRFs can already capture up to 90% of our collected PET and HDPE with existing identification machinery,” he says. “The issue is that our 90% recovery rate isn’t starting with a 100% collection rate.”

Read also points to the quality of collected material as being another barrier to higher recycling rates.

“Many recyclable products do not make it through the MRFs; if you leave liquid in a PET bottle or food in an HDPE tray, it becomes heavier and changes the density, it will not make it onto the recycling pile.”

All this points to needing more consumer awareness of correctly preparing and disposing of waste for recycling.

“It’s a hard message,” says Read. “If you’re trying to get people to get involved and recycle, that’s a relatively straightforward message. Trying to get people to do it right and up the quality is more difficult.”

The rise of on-pack recycling labels

The consumer goods forum has a set of 9 Golden Rules for designing packaging for recyclability, including using on-pack recycling instructions to help with consumer awareness.

Indeed, in March of 2023, a report from the US-based Recycling Partnership suggested that 78% of US consumers look for recycling information on product labels to ensure an item ends up in the right place.

“More accurate recycling at the household level would change my feedstocks in a way that would make it easier whatever system we use,” says Read. “Whether using current technology, manual sorting, a new system, or something hybrid, if you’ve got the right materials, the system will flow.”

Consumer demand for recycling labels

Using on-pack recycling labels not only makes things easier for consumers, but it can also add additional brand value. A recent study from McKinsey and NielsenIQ found a ‘clear and material link’ between sustainability claims and consumer spending.

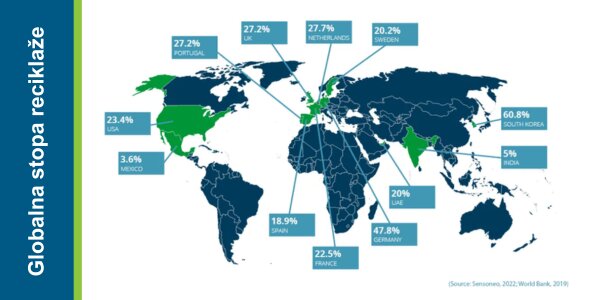

Around the world, recycling labels are gaining traction, with many countries mandating compulsory end-of-life labelling requirements:

- France – Packaging must include the ‘Tri-man logo’, which shows how to dispose of each part of a product’s packaging.

- UK – Producers will need to label all packaging types except flexibles with ‘recycle’ or ‘don’t recycle’ by March 2026, with flexibles following in 2027.

- Italy – Packaging intended for end consumers must indicate the material of the packaging and be clearly labelled with appropriate instructions for disposal.

The list is not exhaustive, with many other countries, including Spain, Portugal, Poland, and Germany, expected to introduce compulsory regional labelling requirements in the coming years.

In other regions, organisations have emerged to provide voluntary on-pack recycling labels for brands:

- North American How2Recycle scheme

- Australasian Recycling Label

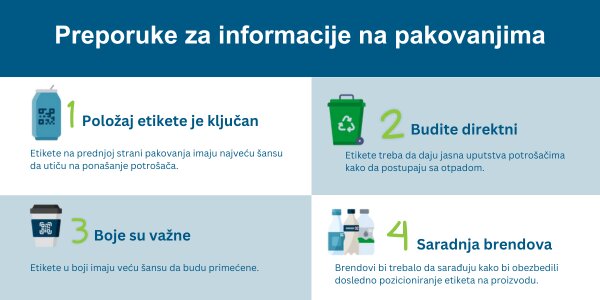

In a 2020 report into consumer behaviour and recycling labels, the Waste and Resources Action Programme in the UK, highlighted a number of recommendations on what a potentially ‘best performing’ recycling label might look like, including:

- Placement is key: Labels on the front of the pack have the best chance of influencing consumer behaviour.

- Be directional: Labels should instruct consumers on how to handle the waste.

- Colour code it: Coloured labels have more chance of being noticed.

- Be consistent: Brands should work together to provide consistent label placement.

A future-proof solution

While there is clearly merit in adding on-pack recycling advice for consumers, having multiple regional labelling requirements can prove confusing and make it difficult for brands selling products internationally, especially where legislation and advice are prone to change.

A potential solution could be to include recycling information within a 2D code, such as a QR code. In fact, the new French labelling laws already mandate that QR codes be added to specific packaging types to give consumers access to recycling information at the scan of a smartphone.

The move by global standards agency, GS1, to see 2D barcodes at the point of sale by 2027 also opens the door for the GS1 Digital Link – a single 2D code to be used at the point of sale and to take consumers to a product-specific webpage to guide them to more information about the product using their phone. GS1 suggests that QR codes powered by the GS1 Digital Link standard could offer businesses an efficient and cost-effective solution for providing recycling information to consumers while future-proofing their packaging against new legislative demands.

With a GS1 Digital Link QR code, brand owners can link to any number of information sources all from one symbol, including:

- Information on what materials make up the constituent parts of the packaging.

- How to prepare the material for recycling, with tips on separating packaging, whether to clean the product, and if specific items (such as caps and pumps) need to be removed or left in place.

- Information on whether an item is widely recycled or if a consumer should check local facilities or use specialist waste recovery.

- Tailored local information via geolocation, or postal code, to allow consumers to:

- Check local recommendations.

- Link to the closest recycling facility.

- Additional consumer interaction:

- Incentives for recycling.

- Tips for reusing packs where products can’t be recycled.

- Feedback and surveys.

Crucially, using a GS1 Digital Link allows brands to update or publish new messaging without altering their packaging design. The information in the GS1 Digital Link QR code can be updated as and whenever new legislation comes online.

By adding a GS1 Digital Link on product packaging today, brands can meet current consumer and business demands and tackle any future requirements as and when needed through a single, flexible, and cost-effective solution.

For more information contact us.