Sisma Fiber lasers

Sisma lasers are ideal for the companies that require the quality and the reliability in the materials, in any manufacturing sector.

The Sisma models: OEM, Easy, Big Smark 800C, BSS 3D, BSP - 3-axis laser marking and engraving system with base, BSP PICO, Sarty, Sart, LWS-A, SWA, MySINT 100, MySINT 300.

.jpg)

The Lasers can be equipped with the integrated (standard for OEM versions), or external computer. Two options are available:

1. The OEM configuration source, suitable for simple applications of marking and other specific applications, such as integration in automatic lines;

2. “PLUS” configuration source, which is suitable for the applications which require the additional tools, such as the rotary addition, the manual Z-axis, the feeder of tiles, the strap puller.

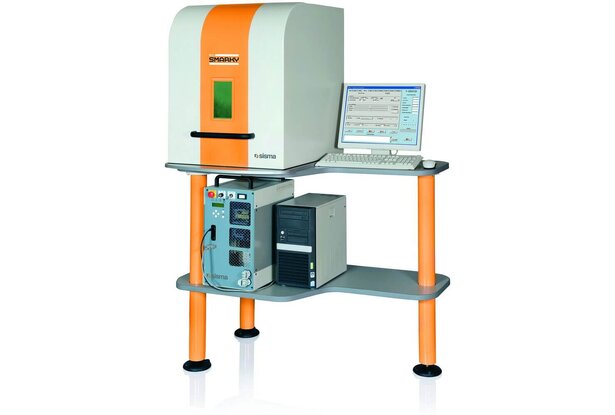

The innovative "all in one" system for laser marking, which is characterized by the great flexibility to users, equipped with a motorized Z-axis, with the high precision and speed. The device has a large glass window and the interior LED lighting.

It is available in versions, closed in class 1 and open in Class 4 protection, as well as in four power versions: 6 W, 12 W, 20 W i 40 W.

.jpg)

.jpg)

Flexible and cost-effective laser system, for marking of plastic and metal materials, even the large ones. The 415mm Z-axis, with high-quality source of the laser beam, has the possibility of marking in the field of 180x180 mm and a spacious working chamber. Big Smarky enables integration of additional devices, such as the micro-changers and the rotary tables, suitable for production without the operator. It is managed by a laptop, or by a fixed PC with the help of SLC software.

Laser for marking and cutting with protection class 1. It is equipped with the focus lens 100 for the marking field of 70x70mm; with the water/air cooling system; the working desk with the computer and a 19'' monitor associated with software, the machine which provides the automatic Z axis. Power is 80 W.

.jpg)

.jpg)

Laser machine for marking and engraving that uses a picosecond laser source, which generates pulses lasting only a few picoseconds with such high intensity that nonlinear/multiphoton absorption occurs. The result is a process with a very reduced thermal effect, ideal for making precise, fluid and clean markings without the need to rework parts.

BSP PICO has a compact and solid structure thanks to the granite work surface, which guarantees excellent process stability for pieces weighing up to 20 kg. The basic construction includes 3 motorized axes with a precision of movement of 50 µm, per field of 300 x 300 mm with an amplitude along the Z axis of 360 mm.

This kind of integrated software is the ideal solution for managing files and the entire marking process, even in the case of complex jobs. BSP PICO guarantees a high degree of speed adaptation and simplifies the operator's work.

.jpg)

An elegant, flexible and reliable system with a rotary table with a diameter of 500 mm, with two positions and a precision of 0.1 mm deviation. Due to its flexibility and productivity, Sarty is an ideal solution for large, serial production. The SLC management software offers several possibilities of multiple marking as well as marking of different automatic or variable data.

This marking laser has a rotary table with a diameter of 700 mm can mark objects with dimensions up to 300x300x150mm. Sart is equipped with a cooling system, a work desk, a computer with a 19'' monitor and accompanying software. The device includes an automatic Z axis. It has a power of 50 W.

.jpg)

.jpg)

Laser system intended for high-quality marking of large pieces. The source of the laser beam can be moved along the Z axis for the LWS-M version, and along 3 axes X-Y-Z for the LWS-A version. The system can be equipped with a configuration of the 1st or 4th Class of protection with the possibility of reducing or eliminating parts. The system is unique in its high level of flexibility. It supports every laser beam source of the SISMA SPA range.

Sisma SWA laser precisely performs even the most complex operations: precise welding around the perimeter, work on hard-to-reach surfaces, filling, covering cracks and damage on tools, all without changing the properties of the material.

Functions such as welding head positioning and rotation provide enormous flexibility, making the Sisma SWA laser adaptable to all needs. The application of this type of laser for tool repair and maintenance is easy to use even on internal and harder-to-access parts of tools and other irregularly shaped metal products.

.jpg)

MySINT100 is a 3D printer with a fusion laser that selectively melts metal powder. Thanks to the patented Tilting Coater, MYSINT100 offers reduced re-coating times, increasing the production capacity. The stable and uniform flow of inert gases ensures the best fusion stability minimizing consumption (patented system).

MySINT 300 is a versatile 3D printer where every processing parameter and the entire production strategy are fully customizable to adapt to each specific need.

It's easy to use - it has removable cylinders for quick and easy powder changes, with very short restart cycle times. The circular shape of the platform avoids material scattering.

It is also productive - the system does not require any powder refilling or emptying during the work cycle, ensuring continuous production at full capacity.

.jpg)

We use cookies to improve your experience. By continuing to visit this page, you accept our use of cookies. Privacy Policy