Pallet labeling

Domino M-series print and apply labelers are the ideal solution for ensuring the logistic traceability of pallets in your warehouse and throughout the entire distribution chain.

With its innovative design, allowing one, two or three sides of the pallet to be labelled, you can rest assured that all safety features and operator-friendly aspects have been considered.

The cabinet will give your pallet labeller maximum protection in an often harsh end-of-line environment and extend the product lifetime, giving you a cost-effective pallet labelling equipment for many years to come.

Regardless if you want to apply a…

Pallet label (warehousing),

Transport label (STILL - Standard International Logistic Label) or a

Store and customer label

...all your logistic units will have one or more readable and perfectly applied GS1 label(s) containing an SSCC (Serial Shipping Container Code), making sure you can track and trace your products.

By integrating the pallet labeller into your company's ERP system, you can guarantee traceability throughout the track and trace process.

By integrating pallet labeling into your company's ERP system, you can guarantee traceability throughout the entire process of tracking products.

For your complete peace of mind, we offer genuine Domino consumables. They were designed and developed specifically for Domino printers, to increase print quality and significantly reduce unplanned downtime.

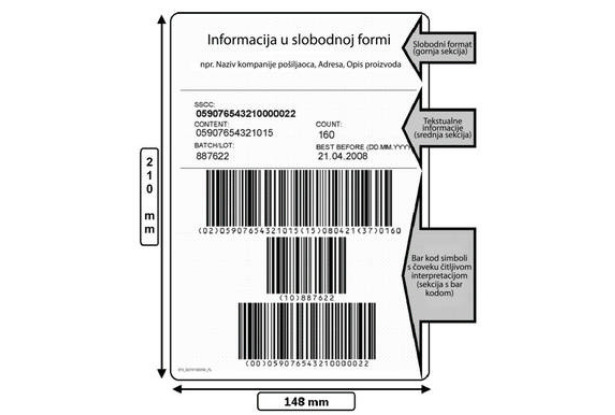

GS1 Logistic Label consists of three sections.

If there is a need for more data, it is recommended to use A5 (148 mm x 210 mm) pallet labels.

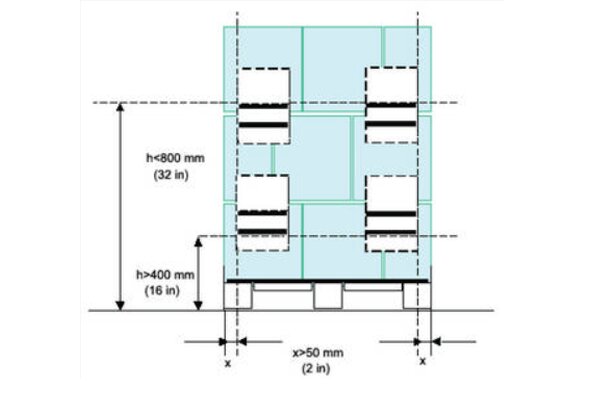

Two identical labels are placed on the pallet, one on the shorter side and the other on the longer side of the pallet.

Labels would be placed on pallets so that the barcodes are between 400mm and 800mm from the base of the pallet, and no closer than 50mm from the vertical edge of the pallet.

We use cookies to improve your experience. By continuing to visit this page, you accept our use of cookies. Privacy Policy