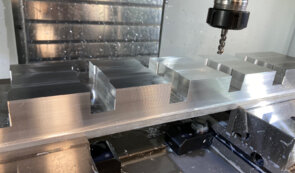

CNC machine for metal cutting

CNC metal machining services

CNC machining is a manufacturing process where the raw material is removed with various precision cutting tools to make the desired part or product. Advanced software is used to control the equipment according to the specifications of your 3D design or designs made for you by our engineers based on instructions.

Our team of engineers and operators program equipment to optimize cutting time, finishing and final tolerance according to your requirements.

We use advanced equipment control software according to 3D design specifications made by our engineers in consonance with your instructions.

Production of complete parts and components as well as machining-finishing of existing parts is performed on three-axis CNC machining centers of the HAAS brand.

Our development department makes the components

- By scraping and

- By milling

We make scraping and milling on alloys of steel, aluminum, brass, bronze, copper, industrial plastics…

We perform CNC machining on the basis of client documentation and assessment of machining possibilities on the machine.

Scraping is a process where removing sawdust results in cylindrical surfaces if the scraping is longitudinal, and flat surfaces if the scraping is transverse.

Scraping is the process of processing materials, primarily rotating parts (screws, nuts, shafts, shafts, bushings, pulleys, ...).

Scraping can be divided into:

- internal and external

- axially and radially

For each of these types it is necessary to use the appropriate tool.

We make service scraping from several different materials, such as steel alloys, stainless steels, aluminum, brass, bronze, industrial plastics, etc.

We can process:

- bars (round, rectangular and hexagonal)

- pipes (round and profiles)

Milling is a process of processing flat surfaces, grooves, profiled contours, surfaces of special and complex shape.

The basic operations in milling are processing:

1. flat surfaces

2. curvilinear contours

3. surface of special shape

4. a surface of complex shape

Processing of flat surfaces is a process of horizontal, vertical or inclined surfaces, production of channels and grooves on flat and cylindrical surfaces (grooves for wedges), cutting, processing of stepped surfaces, etc.

The processing of curvilinear contours is the process of profiled surfaces, protrusions, recesses, roundings, helical grooves, complex contours, etc.

Production and processing of surfaces of special shape by milling is the production of T - grooves, prism profiles, grooves in the form of "dovetail", surfaces with a larger number of steps, rectilinear and curvilinear grooves, etc.

For any additional questions, please send an email to: CNC@elmedint.com